Cody Bateman is an American businessman, scientist and philanthropist. He was the founder of Advantex Research, Cryotek, GenH2, and now MetaVista. Bateman is widely recognized as a leader in the field of hydrogen infrastructure research and development and is an outspoken advocate for the Hydrogen Economy. Currently, he is under contract with Forbes on his first book due out late 2024, Star Powered: Transforming Our Future Through Hydrogen Energy.

Cody Bateman grew up in the oil town of Luling, Texas, the son of two schoolteachers.

Philanthropy was also always a big part of young Cody’s life, joining his parents as they gave out food, clothing and holiday gifts to less-fortunate members of the community. By high school, Cody was finding his own ways to give back by teaching students from the Texas School for the Blind how to canoe in the Blanco River.

Revisiting his roots, Cody purchased Luling’s historic 100-year-old Ainsworth Inn and opened the first full bar in town to provide a gathering place to meet with friends and enjoy great live music.

Cody Bateman graduated from Texas A&M University in 1985. Although his degree was in Computer Science, his favorite class in college was Quantum Physics because it opened his eyes to a new way of thinking that became the core of his career in research and development. He recalls, “On the first day, the professor said to imagine you’re a two-dimensional ant on a piece of paper.”

With that, Cody had the first of many “a-ha” moments in realizing that any object on a piece of paper is, in fact, a line. In contrast to drawing a two-dimensional line on paper, his eventual work in hydrogen would be very different in that you can only imagine what the possibilities are. This became the core of Cody’s post-college career – to imagine possibilities.

Cody Bateman has been active in philanthropic activities his entire life, beginning with helping his parents give out food, clothing and holiday gifts to underprivileged community members in his hometown of Luling, Texas. As he grew, he took on more responsibilities and in high school taught students from the Texas School for the Blind to canoe in the nearby Blanco River.

Over the years, Cody has supported numerous charities throughout the United States, Canada, Mexico, Brazil, Argentina, Hungary, France, China, Thailand, Japan, Russia and Korea. He focuses on helping underprivileged children and has served on the Board of Directors of SAFY, which focuses on foster care.

Cody has also worked with the China Care Foundation which helps orphans with serious medical conditions by providing fragile infants and toddlers with the comforts of home, the love and affection of doting caregivers and nurses, and state-of-the-art medical care to meet their needs prior to and immediately after surgery.

While doing missionary work with the Catholic Church in Mexico, Cody helped rebuild a convent and in Brazil worked with a French organization in Rio de Janeiro to provide job training to very young, unwed mothers who had been abandoned by their families. He finds this work very rewarding and savors each success story, such as that of a child who grew up in a Russian orphanage that he supported who recently celebrated their high school graduation.

Immediately after college, Cody went to work at Texas Instruments in Dallas, Texas where he quickly became the lead engineer on the TOW-2 missile system which later became a key weapon used during Operation Desert Storm.

Two years later, he joined Merit Technology to help design advanced simulation systems for the Department of Defense. In 1990, Advantex Research was formed to further advance simulation technologies and to commercialize much of the technology that was previously used only in the government sector.

Cody distinguished himself early on in his professional career as a pioneer in the field of advanced analytical techniques. He helped to define the concept of Data Warehousing and continues to be globally recognized as one of the founders of Customer Relationship Management (CRM) and Data Mining. He has consulted with executives from multiple Fortune 500 companies to create analytical tools and techniques to help optimize operations and significantly increase profits.

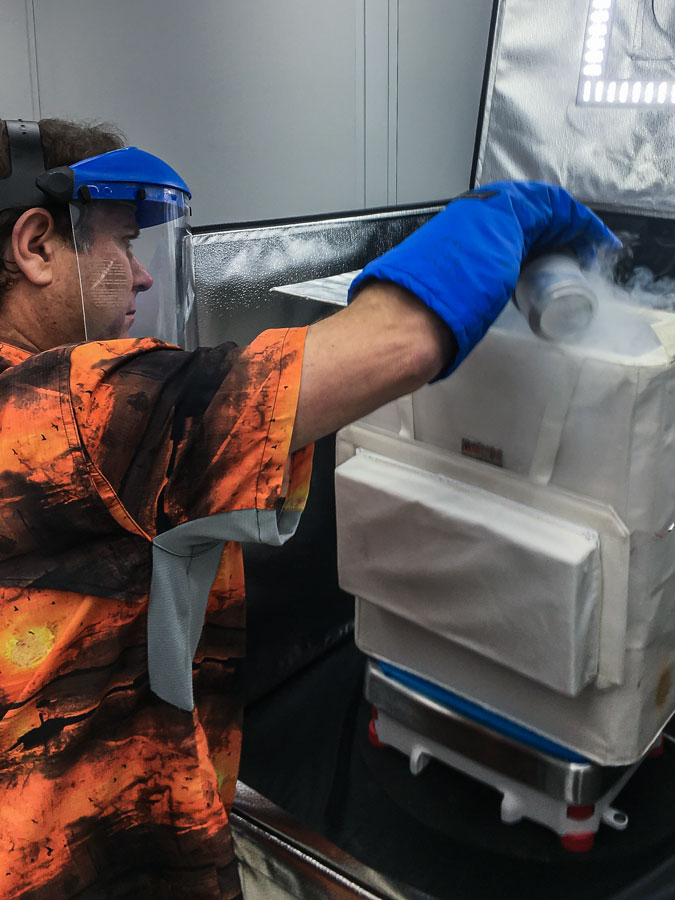

In 2006, Cryotek was formed to focus on the technological advancements of liquid hydrogen (LH2) for vehicles, drones, maritime applications, large scale storage, thermal insulation systems, and supply infrastructure. By 2012, a laboratory in Titusville, FL was created to further research and optimize the combination of multiple technologies to create an advanced cryogenic ‘systems’ in association with the Cryogenics Test Lab at Kennedy Space Center.

After a one-year subatical after handing off the reigns of GenH2, Cody has now relaunched MetaVista began the TrueH2 podcast. In addition, he is providing both consulting and educational services with Process Improvement Partners (www.pi-partners.com).

Cody Bateman’s career path has woven through seemingly diverse routes from CRM and data warehousing to rockets and hydrogen. However, there is a thread linking all his work experiences, and that is data.

First, while exploring data structure and storing data, Cody joined forces with GTE Supply to help the company quantify its inventory movement and came up with the concept of a data warehouse. In 1994, he then took that concept of data warehousing and started working on “conformed dimensions” which became the industry standard.

Cody decided that it would be advantageous to understand the customer as well as GTE could now understand its inventory. By aggregating information on customers and utilizing the ability to look at other companies for sample data, Cody was able to start formulating a customer relationship management system, or CRM. With inventory and CRM data, business intelligence, and predicting how a business was going to do, data warehousing became possible. Even people like Jack Welch were waking up to the importance of data and business intelligence.

While Cody was successful in developing data warehousing, CRM and business intelligence, he still had a passion for rockets and was looking for new ways of getting back to his energy background. He grew up in the oil town of Luling, Texas, so he understood the industry. He soon realized that combining, data, energy and rockets was going to go somewhere.

Cody discovered that the data needed to create algorithms to simulate missile systems are extremely complex; if you have a missile coming at you, things are moving in three dimensions. How do you simulate that? Cody found he was able to apply data garnered from physical properties of jets, knowing speed, acceleration, mass, altitude, and temperature to understand what you’re capable of simulating and predicting for missile systems. However, because that data only simulates, he drew on history and used predictive modeling to do analysis to make the simulation more accurate. The key was to take variables from all different things.

The objective: Controlling an item by knowing all the variables behind it. Applying the data obtained from the many variables to a TOW (Tube-launched, Optically tracked, Wire-guided), optically fired, missile, Cody simulated a guided missile, working on projectiles that you can shoot out of a cannon with the ability to change trajectory while in-flight.

When Cody Bateman was getting out of the defense world, he saw the benefit of getting Apple NEXT technology into the missile system. Not only did he meet personally with Steve Jobs, he won several government defense contracts to do simulations using the NEXT computer. Cody credits Jobs with the universal concept that with any data, you can simulate anything.

Then, Cody started getting calls from executives in the Oil and Gas Industry. There is an enormous amount of data in developing and deploying drilling technology from strata to knowing drill bits to use going into the ground. He knew what to expect from the data to make sure the equipment utilized was correct. For example, drill bits cost millions of dollars, so it’s essential to know which ones you’ll need. In addition, flow rate can be optimized by applying data on what happens when you hit gas or oil.